PEMS

Mobile Exhaust Gas Flow Sensors and Measurement for Passenger Cars and Commercial Vehicles (PEMS)

Since the diesel scandal, the demand for reliable gas mass measurement for portable emission monitoring systems (PEMS) is high. Having exact data on real drive emissions has become even more essential for manufacturers of both passenger and commercial vehicles than before.

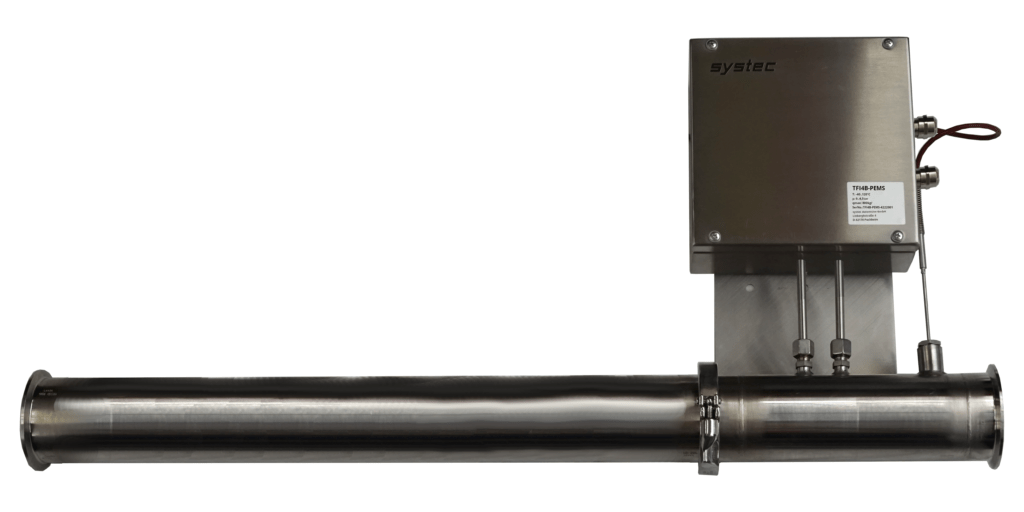

We support you in developing and using PEMS with customized versions of our TFI4B platform. The TFI4B is a sensor system consisting of differential pressure, absolute pressure and temperature sensors. A CAN bus provides the necessary connection to an engine control unit (ECU) or a mobile data logger system. The core electronics have a powerful microprocessor that processes, filters and calculates the signals. This means that we deliver the measurement directly to you and you do not need to use any other resources – our TFI4B platform works as an RDE (real drive emission) meter.

Learn more about our “Mini PEMS”, which we developed in cooperation with the German Federal Motor Transport Authority (KBA). Click here.